PowerTap Gen3 Technology

PowerTap’s Differentiated Technology

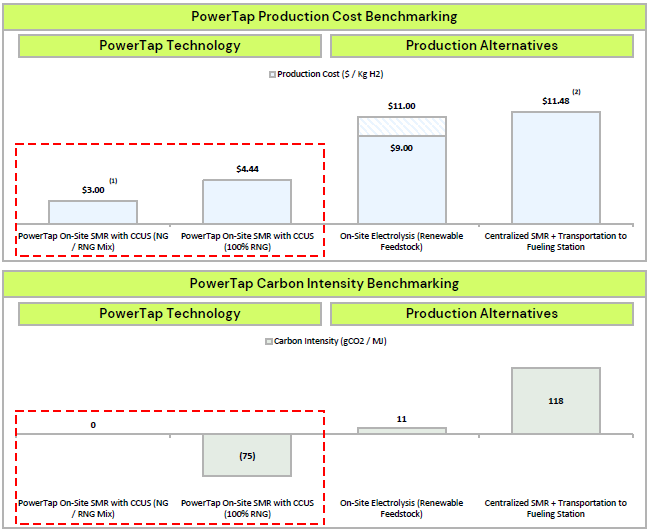

Key Points

- Blue, on-site, low-cost hydrogen production withSMR+CCS, producing zero-carbon fuel withminimal additional infrastructure

- Small footprint – under 1,000 sqft, easy to tie in toexisting gas stations

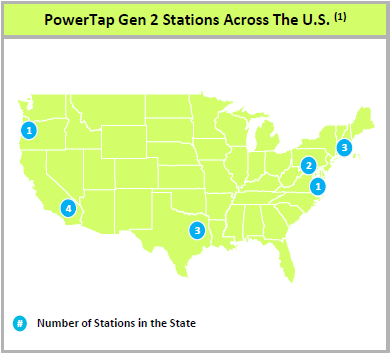

- Operationally tested for over a decade – basedon the PowerTap Generation 2 facility, with 14operating stations in the US (not owned /operated under PowerTap)(1)

- 20+ issued patents focusing on key technology inthe fabrication and reaction catalysts

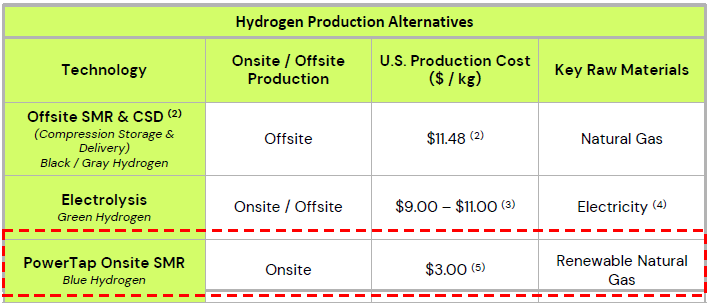

Source: Levelized Cost of Production Calculated by EIN using data from “California Power-to-Gas and Power-to-Hydrogen Near-Term Business Case Evaluation” Eichman, Josh, Flores-Espino, Francisco, National Renewable Energy Laboratory

- Nuvera manufactured and sold PowerTap Gen 2 stations / platforms to third parties

- Cost to individual station owner: most hydrogen fueling stations buy and ship offsite hydrogen fromchemical companies

- Excludes maintenance costs and carbon credit benefits

- Source: The Wall Street Journal, “Betting on Hydrogen”, October 23, 2020

- Production excludes capital expenditure and includes maintenance costs

PowerTap Produces Low CI Hydrogen

Key Points

PowerTap stationsproduce sustainablehydrogen through usingrenewable natural gas(“RNG”) as feedstock andCCUS

- Using RNG allowsPowerTap to achieve negative carbon intensity scores as the full cycle of production is net carbon negative

- All PowerTap stations will be equipped with CCUS to capture CO2 emissions

Source: California Air Resources Board (“CARB”), PowerTap management team estimates. “Production Alternatives” carbon intensity values estimated from existing pathways using CARB methodology.

- Production excludes capital expenditure and includes maintenance costs

- Assumes centralized SMR hydrogen production, gaseous hydrogen transportation, calculated with CA-GREET3.0.

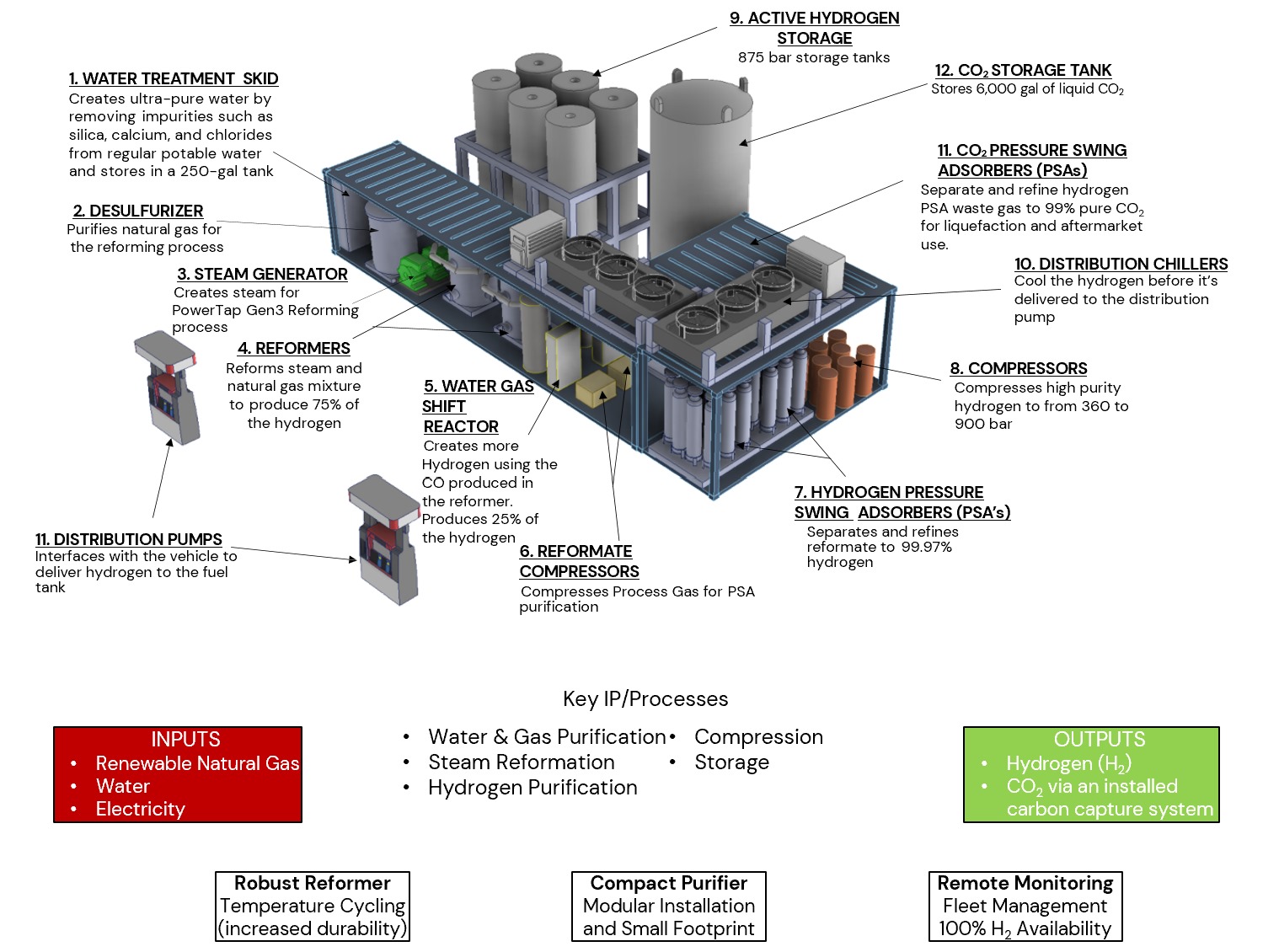

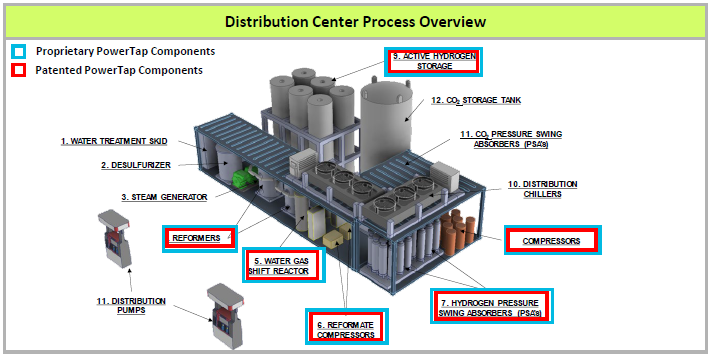

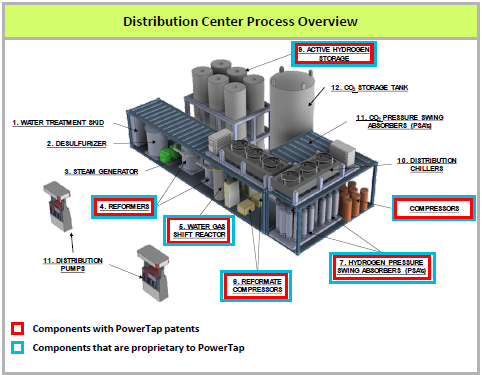

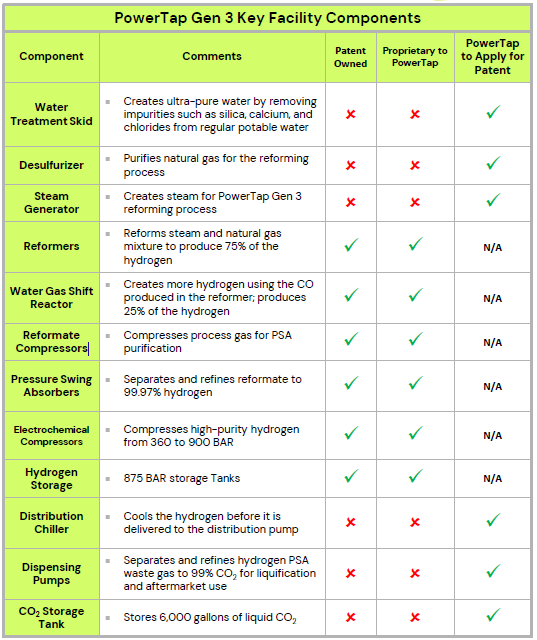

Key PowerTap Facility Components

Key Points

- PowerTap distributed hydrogen stations rely on steam methanereforming technology with a carbon capture technology embedded in the process to remove emissions and lower carbon intensity

- Technology relies on ~10 main components to convert feedstocknatural gas and water to distributable hydrogen

- PowerTap holds active patents for five of these components in theUnited States and abroad

- The Company works with several suppliers in an exclusive capacity tosource the raw components and feedstock of the process

- Renewable Natural Gas

- Hydrogen Generators

Note: Distribution center process overview as of June 2021; design shown is subject to changes

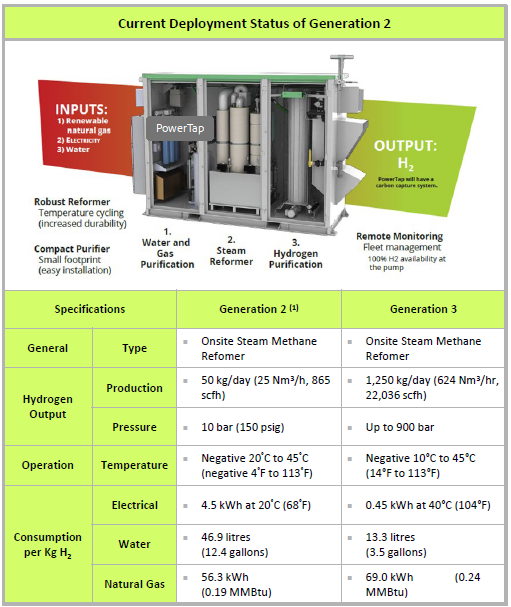

PowerTap Hydrogen Gen3 vs. Gen2

PowerTap Generation 3 vs Generation 2

- Goals

- Build on the current PowerTap Gen2 technology and increase hydrogen production output from 50 kg/dayto 1,250 kg/day (i.e., 25x larger)

- Develop a cost-efficient and environmentally friendly modular steam reformer that respects strict emission regulations

- Build two (2) fully functional Gen3 distribution centers by end of 2022

- Target

- Carbon capturing capabilities that will reduce the amount of the CO2 in the flue gas of the reformingprocess or process for high purity CO2 for commercial markets

Key Innovations

- Desulfurization module

- Injected H2 to create H2S to extend catalysis life from 1 to 8 years

- Steam Methane Reformer

- Lowers reactor’s temperature / pressure to extend vessel’s life span

- Added a reflective coating to create better heat transfer across tubes to increase the reactor’s efficiency

- Steam Shift Reactor

- Front load the input with Reformant compressor to increase H2 production

- Sin gas is recycled to the burner system to decrease the amount of feedstock required to produce heat forthe burners

- Pressure Swing Absorption Module

- Allows for carbon capture (85% of CO2 in tanks onsite) and purified H2 for storage and compression

- Active Storage

- Reduces overall footprint and allows system to draw down on 95% of the total H2 stored vs. currentavailable vs. standard gas and liquid solutions

- Maintains output > 875 bars continuously regardless of gas level

OneH2 acquired all hydrogen generation and production assets belonging to Nuvera Fuel Cells, LLC in February 2019. The acquisition provides OneH2 with a limited license tomanufacture small scale hydrogen generators for forklifts